Logistics and Fulfillment: Ensuring Timely Delivery

Optimizing Warehouse Operations

Efficient warehouse operations are crucial for timely delivery in e-commerce. This involves strategically organizing storage space, implementing automated systems for picking, packing, and shipping, and ensuring that inventory management processes are streamlined. Properly trained personnel, equipped with the right tools, can significantly improve the speed and accuracy of order fulfillment, reducing delays and enhancing customer satisfaction. Well-designed warehouse layouts minimize travel time for picking orders, maximizing efficiency and minimizing potential errors.

Inventory management systems play a vital role in optimizing warehouse operations. Real-time tracking of inventory levels, coupled with predictive analytics, allows businesses to anticipate demand fluctuations and proactively adjust stock levels. This proactive approach minimizes stockouts and reduces the risk of overstocking, thereby optimizing warehouse space and inventory costs. Effective forecasting models are essential for accurate inventory planning and timely order fulfillment.

Transportation and Delivery Networks

Establishing robust transportation and delivery networks is paramount for ensuring timely delivery in e-commerce. This involves partnering with reliable carriers, optimizing delivery routes, and utilizing technologies such as GPS tracking to monitor shipments and provide real-time updates to customers. Strategic selection of transportation partners considering factors like cost-effectiveness, delivery speed, and service reliability is essential for maintaining efficiency throughout the entire supply chain.

Efficient route optimization is crucial for minimizing delivery times. Leveraging route planning software, incorporating real-time traffic data, and considering factors like delivery windows and customer locations contributes significantly to reducing delivery times. This optimization process improves delivery efficiency and ensures packages reach their destinations on time.

Order Processing and Fulfillment

Streamlined order processing and fulfillment procedures are essential for minimizing delays and ensuring that orders are handled efficiently. Implementing a system that automatically processes orders, tracks their progress, and updates customers with real-time information can significantly improve the customer experience. Automated order processing reduces manual errors and speeds up the entire fulfillment process, leading to quicker delivery times. Robust order management systems are vital to ensure accuracy and efficiency in order processing.

Packaging and Handling Procedures

Proper packaging and handling procedures are critical components of logistics and fulfillment. Using appropriate packaging materials to protect products during transit, ensuring that packages are handled with care, and implementing quality control measures throughout the packaging process are essential for maintaining the integrity of products and preventing damage. Properly labeled and securely packaged items minimize the risk of damage during transit, ensuring that products arrive at their destination in perfect condition. Efficient packaging processes directly impact the overall quality of the customer experience.

Returns and Reverse Logistics

Implementing a well-defined return policy and establishing a robust reverse logistics system are vital for managing returns effectively and minimizing disruption to the overall supply chain. Efficient handling of returns, including processing, restocking, and re-shipping, minimizes delays and ensures that products are returned to stock quickly. A streamlined return process is critical for maintaining customer satisfaction and ensuring the smooth functioning of the reverse logistics flow. Clear communication with customers regarding return procedures, and providing options for different return methods, further enhances customer satisfaction and manages the reverse logistics process efficiently.

Technology Integration: Automating and Optimizing Processes

Streamlining Order Fulfillment

Automated order fulfillment systems are revolutionizing supply chain management. These systems integrate seamlessly with various stages of the process, from order placement to delivery. This integration automates tasks like picking, packing, and shipping, leading to significant improvements in efficiency and reduced errors. By automating these repetitive tasks, companies can free up valuable human resources to focus on higher-level strategic initiatives, ultimately driving down operational costs and enhancing customer satisfaction.

Advanced warehouse management systems (WMS) play a crucial role in this automation. They track inventory levels in real-time, optimize storage space, and direct the movement of goods within the warehouse. This real-time visibility allows for more accurate forecasting, better inventory control, and quicker order processing, all leading to improved customer satisfaction.

Optimizing Inventory Management

Technology empowers supply chain managers to optimize inventory levels with precision. Real-time data feeds from various sources, such as sales forecasts and production schedules, allow for more accurate inventory predictions. This reduces the risk of stockouts or excess inventory, minimizing storage costs and the potential for obsolescence. Advanced inventory management software can predict demand patterns with greater accuracy, enabling proactive adjustments to inventory levels and mitigating potential disruptions.

Predictive analytics tools analyze historical data and market trends to forecast future demand. This allows companies to adjust inventory levels proactively, ensuring they have the right amount of stock on hand at the right time, which directly impacts profitability and customer satisfaction.

Enhanced Visibility and Tracking

Real-time visibility into every stage of the supply chain is crucial for effective management. Advanced tracking technologies, such as GPS and RFID, provide comprehensive visibility into the location and status of shipments, enabling proactive management of potential delays or disruptions. This enhanced visibility allows for quicker identification of problems and swift implementation of corrective actions, minimizing potential losses and ensuring timely delivery.

This transparency also builds trust with customers, who appreciate knowing the location and status of their orders. Detailed tracking information fosters greater customer satisfaction, loyalty, and confidence in the supply chain's reliability.

Data-Driven Decision Making

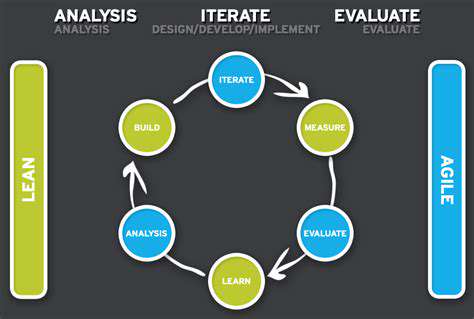

The integration of technology generates vast amounts of data about every aspect of the supply chain. This data can be leveraged to make more informed and strategic decisions, resulting in significant improvements in efficiency and cost savings. By analyzing this data, companies can identify bottlenecks, inefficiencies, and areas for improvement in their operations.

Advanced analytics tools can uncover hidden patterns and trends in the data, enabling proactive adjustments to optimize processes and prevent disruptions. This data-driven approach allows for a more agile and adaptable supply chain, better positioned to react to market fluctuations and changing customer demands.

Improved Collaboration and Communication

Technology facilitates seamless communication and collaboration among all stakeholders involved in the supply chain, from suppliers to manufacturers to distributors and retailers. Cloud-based platforms and communication tools enable real-time information sharing, improving coordination and reducing delays. This enhanced collaboration fosters a more efficient and responsive supply chain, allowing for quick responses to changing circumstances and demands.

Automated communication systems ensure timely updates and notifications to all parties involved, keeping everyone informed about the status of orders, shipments, and production. This transparency and efficient communication contribute to a more streamlined and reliable supply chain process.

Security and Risk Management

As supply chains become increasingly digitized, ensuring the security of sensitive data and mitigating risks becomes paramount. Robust cybersecurity measures are crucial to protect against cyberattacks and data breaches, safeguarding sensitive information and maintaining the integrity of the supply chain. This includes implementing strong access controls, encryption protocols, and regular security audits to protect against potential threats.

Advanced risk management tools can identify and assess potential disruptions, such as natural disasters, geopolitical events, or supplier issues. This allows companies to develop contingency plans and proactively mitigate risks, ensuring the resilience and continuity of their supply chains.