Enhancing Supply Chain Resilience with AI

Understanding the Criticality of Resilience

Supply chain resilience is no longer a desirable feature but a critical necessity in today's volatile global landscape. Disruptions, from natural disasters to geopolitical instability, can quickly cripple even the most robust supply chains. Understanding the inherent vulnerabilities within your network and proactively developing strategies to mitigate these risks is paramount for long-term success and profitability.

Proactive identification and mitigation of potential disruptions is key to building a resilient supply chain. This necessitates a comprehensive understanding of your entire supply chain, from raw materials to finished products, and the potential points of failure at each stage.

Diversifying Sourcing Strategies

Over-reliance on a single supplier or geographic region significantly increases vulnerability. Diversifying sourcing strategies by establishing relationships with multiple suppliers in different locations allows for greater flexibility and adaptability in the face of unforeseen circumstances. This diversification creates a buffer against disruptions in a single location or supply chain.

This approach also allows companies to leverage different cost structures and production capabilities, potentially leading to improved efficiency and cost savings in the long term.

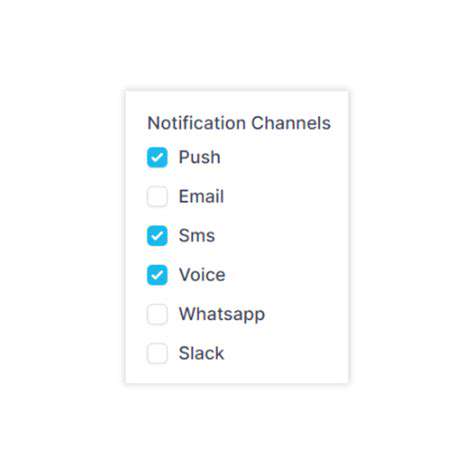

Improving Visibility and Transparency

Real-time visibility into the movement of goods and materials throughout the supply chain is crucial for effective management. Advanced tracking technologies and data analytics tools enable businesses to monitor inventory levels, anticipate potential bottlenecks, and make informed decisions to proactively address disruptions. This enhanced visibility leads to faster reaction times and more efficient resource allocation.

Investing in Redundant Capabilities

Investing in redundant capabilities, such as backup suppliers, alternative transportation routes, and excess inventory, provides a crucial safety net during times of crisis. These redundancies act as a buffer against unexpected disruptions, ensuring uninterrupted production and delivery of goods to customers.

Strengthening Relationships with Stakeholders

Strong relationships with suppliers, distributors, and other stakeholders are essential for building resilience. Open communication and collaboration facilitate a shared understanding of potential risks and opportunities, allowing for proactive problem-solving and a coordinated response to disruptions.

Effective communication and collaboration foster trust and mutual support, crucial for navigating challenges and ensuring long-term sustainability.

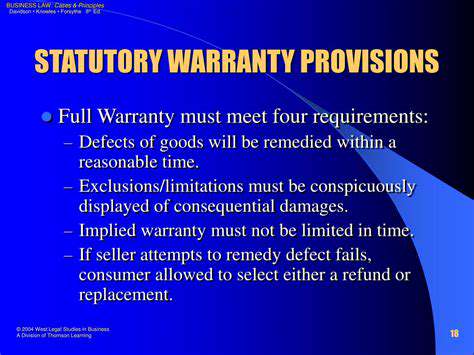

Implementing Robust Risk Management Strategies

A comprehensive risk management strategy is an indispensable component of a resilient supply chain. This involves identifying potential risks, assessing their likelihood and impact, and developing mitigation plans. This proactive approach allows companies to anticipate and address potential disruptions before they escalate into major crises.

Regularly reviewing and updating risk assessment protocols and mitigation strategies is essential to ensure that the supply chain remains adaptable to evolving market conditions and emerging threats. This adaptability and proactivity ultimately contribute to the long-term stability and success of the company.