Optimizing Inventory Management for Speed and Accuracy

Understanding Inventory Costs

Inventory management is crucial for any business, and a significant portion of operational costs is tied to inventory. Understanding these costs, from storage and insurance to obsolescence and potential spoilage, is paramount. This detailed analysis of inventory costs allows businesses to make informed decisions about inventory levels and optimize their supply chain. A robust understanding of carrying costs, such as warehousing, handling, and financing, is essential to minimizing expenses and maximizing profitability.

Beyond the direct costs, indirect costs like lost sales due to stockouts or the opportunity cost of tying up capital in excess inventory must also be considered. These factors have a substantial impact on the bottom line and should be factored into the overall inventory strategy. Thorough cost analysis is the bedrock of any effective inventory management system.

Demand Forecasting Techniques

Accurate demand forecasting is critical for maintaining optimal inventory levels. Employing various forecasting methods, such as time series analysis, regression models, or even qualitative methods like expert opinion, can significantly improve inventory accuracy. These techniques help predict future demand fluctuations and ensure that the right amount of inventory is available when needed.

Statistical forecasting models, which rely on historical data, are frequently used. However, incorporating external factors like market trends, economic indicators, and seasonal variations is equally important for a more comprehensive and accurate prediction. This allows businesses to anticipate changes in demand and make proactive adjustments to their inventory levels.

Inventory Control Systems

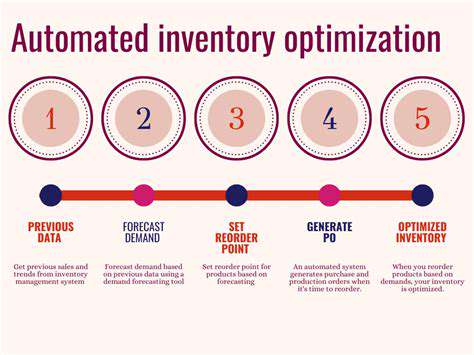

Implementing an effective inventory control system is essential for tracking inventory levels in real-time. This system should enable businesses to monitor stock levels, identify potential shortages or surpluses, and trigger automatic replenishment orders. Real-time visibility into inventory movements is crucial for optimizing stock levels.

Choosing the right inventory control system depends on the specific needs and size of the business. From basic spreadsheets to sophisticated Enterprise Resource Planning (ERP) systems, there's a solution for every scale of operation. Implementing a robust system streamlines operations and reduces the risk of stockouts or overstocking.

Optimizing Storage and Handling

Efficient storage and handling practices are key to minimizing inventory costs and maximizing space utilization. Careful consideration of storage space layout, appropriate shelving, and proper handling procedures can significantly impact inventory turnover and reduce damage or loss. Efficient storage is not just about finding more space, but also about minimizing wasted space and streamlining access to inventory.

Supplier Relationship Management

Strong relationships with suppliers are crucial for a smooth and efficient inventory management process. Developing strong communication channels and establishing clear expectations about order fulfillment and delivery times ensures a reliable supply chain. Collaboration and trust between businesses and their suppliers are essential for maintaining optimal inventory levels.

Negotiating favorable terms and conditions with key suppliers, potentially through bulk purchasing or long-term contracts, can greatly reduce procurement costs and ensure consistent supply. This relationship-oriented approach fosters a collaborative environment that benefits both parties.

Inventory Turnover Rate

Monitoring and improving the inventory turnover rate is vital for assessing the efficiency of inventory management. A high inventory turnover rate indicates that goods are moving quickly through the supply chain, reducing storage costs and the risk of obsolescence. This metric directly impacts profitability and efficiency.

Analyzing the inventory turnover rate helps identify slow-moving or obsolete inventory, enabling businesses to make informed decisions about disposal or s. Understanding the turnover rate provides valuable insights into the overall health and efficiency of the inventory management process.

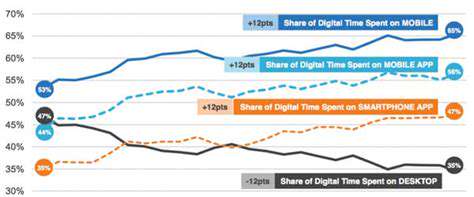

Technology Integration

Leveraging technology, such as inventory management software and automated systems, can significantly improve efficiency and accuracy in inventory management. These tools streamline processes, reduce errors, and provide real-time data for informed decision-making. Integrating technology into your inventory management strategy can drastically improve accuracy and efficiency.

Automated systems can track inventory levels, trigger re-ordering, and provide detailed reports on inventory performance. This level of automation minimizes human error and frees up valuable time for other business tasks.

Tailoring Delivery Options for Enhanced Customer Satisfaction

Optimizing Shipping Strategies for Diverse Customer Needs

Delivering exceptional customer experiences hinges on understanding and catering to varied shipping preferences. This involves analyzing factors like geographic location, order size, and product fragility. By segmenting customers based on these characteristics, businesses can tailor shipping methods to minimize delivery times, maximize package security, and ultimately, enhance overall satisfaction. This proactive approach not only builds trust but also fosters brand loyalty by demonstrating a commitment to meeting specific needs.

Different delivery options, from expedited shipping to international shipping, each come with varying costs and timeframes. Understanding these nuances allows businesses to offer a range of choices, empowering customers to select the option that best aligns with their priorities. This flexibility is crucial for retaining customers and expanding market reach.

Leveraging Real-Time Tracking for Transparency and Control

Integrating real-time tracking systems into the fulfillment process provides customers with crucial visibility into their package's journey. Knowing the precise location and expected delivery time fosters a sense of control and reduces anxiety associated with waiting. This transparency is invaluable in building customer trust and confidence in the company's ability to manage shipments efficiently.

Implementing Robust Return Policies for Customer Confidence

A clear and comprehensive return policy is essential for mitigating potential customer dissatisfaction. Providing detailed instructions on the return process, including acceptable reasons, timelines, and associated costs, can significantly reduce the risk of negative experiences. A smooth and straightforward return process reassures customers of the company's commitment to their satisfaction and allows for a more positive resolution in the event of a problem.

Streamlining Order Processing for Faster Turnaround Times

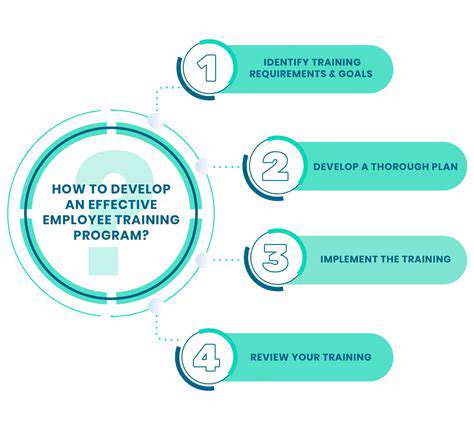

Efficient order processing is paramount to achieving quick turnaround times and delivering exceptional customer service. Automation tools and optimized workflows play a critical role in streamlining the entire process, reducing manual intervention and minimizing errors. By implementing these tools effectively, businesses can ensure that orders are processed accurately and dispatched promptly, ultimately leading to greater customer satisfaction.

Exploring Alternative Delivery Methods for Unique Scenarios

Beyond standard shipping options, businesses should explore alternative delivery methods to cater to specific customer needs or situations. This could include partnerships with local delivery services, locker-based deliveries, or even exploring drone delivery options in certain areas. By providing diverse choices, companies can ensure that their delivery network accommodates a broader range of preferences and scenarios, resulting in a more personalized and efficient customer experience.

Analyzing Data to Refine Delivery Strategies for Ongoing Improvement

Regularly analyzing delivery data is crucial for identifying areas for improvement and optimizing fulfillment strategies. Collecting and evaluating metrics like delivery times, shipping costs, and customer feedback allows businesses to gain valuable insights into their processes. These insights can be used to refine delivery strategies, identify bottlenecks, and make data-driven decisions that enhance overall customer satisfaction and operational efficiency. This continuous improvement cycle is vital for staying competitive and responsive to evolving customer expectations.