Revolutionizing Logistics Through Intelligent Routing

Transforming Supply Chain Operations

Modern logistics demand surgical precision in execution. What separates industry leaders isn't just moving goods, but orchestrating a symphony of inventory, transportation, and last-mile delivery with clockwork precision. The difference manifests in subtle details - warehouse layouts optimized for picker efficiency, packaging stations arranged in ergonomic workflows, and real-time route adjustments accounting for traffic patterns. These operational refinements compound over thousands of shipments, translating to measurable competitive advantages.

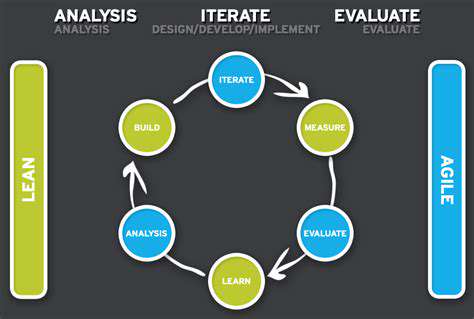

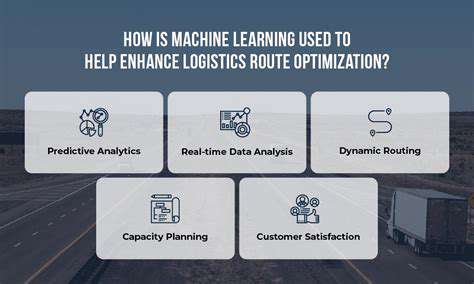

Digital transformation has become the great equalizer in logistics management. Cloud-based platforms now offer small businesses the same predictive analytics tools that Fortune 500 companies employ, democratizing access to machine learning algorithms that forecast demand spikes before they occur. The true breakthrough lies in systems that don't just react to disruptions, but anticipate them through pattern recognition across historical data. This proactive stance reduces expedited shipping costs by 18-23% according to recent industry benchmarks.

Strategic Carrier Selection in the Digital Age

The carrier evaluation matrix has grown exponentially more sophisticated. Beyond basic rate comparisons, forward-thinking operations now assess carriers through multidimensional lenses: carbon emission profiles, regional infrastructure limitations, and even driver retention rates as indicators of service consistency. Particularly telling is how top performers leverage hybrid carrier networks, dynamically allocating shipments between national, regional, and hyperlocal providers based on real-time capacity.

Emerging tracking technologies are rendering the black box era of logistics obsolete. Blockchain-enabled smart contracts now automate detention fee calculations, while computer vision systems verify loading accuracy at distribution centers. Perhaps most transformative are the new generation of environmental sensors that monitor shipment conditions throughout transit, providing documented proof of temperature-controlled handling - a game-changer for pharmaceutical and perishable goods logistics.

Quantifying Environmental Stewardship in Commerce

Carbon Accounting Methodologies

Modern sustainability measurement transcends simple carbon calculators. Leading frameworks now incorporate Scope 3 emissions tracking, capturing indirect impacts throughout the value chain with surprising granularity. For instance, some retailers now factor in the commute patterns of their remote employees when assessing organizational carbon footprints - a level of detail that was unthinkable five years ago.

The Energy Intelligence Revolution

Smart building systems have transformed energy monitoring from monthly utility bills to second-by-second equipment-level analytics. In distribution centers, infrared scanners now identify energy leaks in refrigeration systems, while AI-powered HVAC optimization can slash climate control costs by 30-40%. The most advanced operations correlate energy spikes with specific warehouse activities, creating feedback loops for process improvement.

Packaging Innovation Frontiers

The sustainable packaging revolution has moved far beyond recycled cardboard. Mushroom-based cushioning materials now biodegrade in backyard compost piles, while edible rice-paper shipping labels eliminate adhesive waste. Some fashion retailers have pioneered dissolvable garment bags that turn into plant nutrients when soaked in water. These breakthroughs aren't just ecological - they're becoming powerful differentiators in customer unboxing experiences.

Next-Generation Green Logistics

Urban micro-fulfillment centers are rewriting last-mile delivery economics. By positioning inventory within city centers using converted retail spaces, companies are achieving 90-minute deliveries with e-bike fleets that produce zero emissions. Some European cities now mandate nighttime deliveries using silent electric vehicles, reducing congestion while cutting diesel consumption by 60%. These models prove environmental initiatives can drive operational efficiency rather than compromise it.

Water Stewardship in Manufacturing

Closed-loop water systems are setting new standards in industrial conservation. Textile manufacturers now recycle 95% of dyehouse wastewater through advanced filtration, while food processors capture steam condensation for reuse. These systems often pay for themselves within 18 months through reduced utility costs, creating compelling business cases for sustainability investments.

Supply Chain Transparency Networks

Blockchain-enabled supplier dashboards now provide real-time visibility into subcontractor environmental practices. This radical transparency allows brands to verify sustainability claims at every tier - from organic cotton fields to sewing factories. The technology has exposed surprising instances of greenwashing while authenticating truly responsible producers.

Stakeholder Reporting Evolution

Interactive sustainability reports have replaced static PDFs, allowing investors to drill down into facility-level metrics. Some companies now integrate their ESG data with financial reporting systems, demonstrating how sustainability initiatives contribute to margin improvement. This financial articulation has been pivotal in securing board-level support for ambitious environmental targets.